How To Select A Power Moller Fittings ITOH DENKI Vietnam | ITOH DENKI Việt Nam

1 – Material: What is in contact with the Motorized Roller?

- Metal

- Plastic

- Wood

- Urethane

- Natural rubber

- Corrugated cardboard

- Other material

2 – Product weight: What will be the maximum weight?

3 – Available voltage: What voltage are you using?

- 24VDC

- 3 230VAC @ 60Hz

- 1 115VAC @ 60Hz

- Other Voltages

4 – Desired transportation speed: How fast do you want to move the article?

- Feet/minute (FPM)

5 – Diameter of the roller: What diameter are you looking for?

Common Itoh Roller Diameters

Common Itoh Roller Diameters

- 1.50” (38.0mm)

- 1.68” (42.7mm)

- 1.91” (48.6mm)

- 2.25” (57.0mm)

- 2.38” (60.5mm)

- 2.50” (63.5mm)

- 3.00” (76.3mm)

(Convert English units to Metric units, 1 inch=25.4 mm)

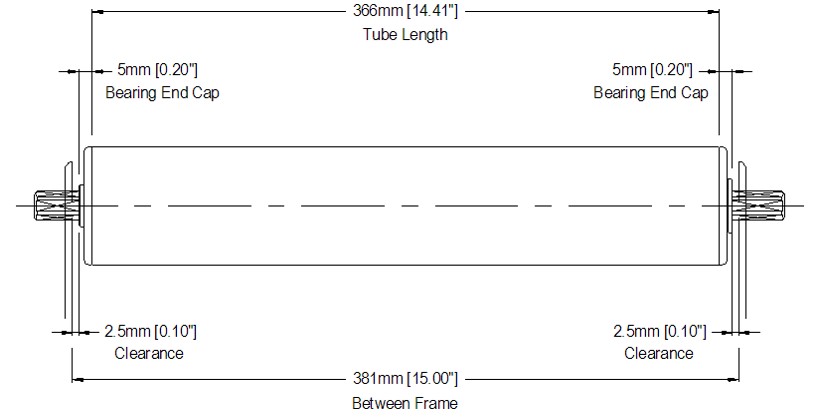

6 – Between frame dimension: What is your between frame dimension (BF)?

- In determining the correct length of the Power Moller required, you should first obtain the between the frame width of the conveyor you will be mounting the Power Moller in.

- All dimensions need to be converted to millimeters.

- Take the between the frame width and subtract 15mm to account for bearing end caps and clearances to achieve proper tube length.

- Subtract 21mm when using the “JQ” type shafts.

- For the PM635FS the deduction will be 20mm

- For PM763BS deduct 30mm

- For IP-G and HP-G rollers, deduct 35mm.

7 – Options: Does the application call for any special options?

- Lagging (Natural Rubber, NBR, Neoprene, Urethane)

- Dust-proof

- Waterproof

- Brake

- Clutch

- Other

- KF – Brackets not ordered with roller

Important Formulas:

Tangential Force (TF)

- Tangential force is the force in lbs. that is needed to move the item on the conveyor.

- The force tangent to the roller’s surface.

- Tangential force F can be found by the following formula:

Formula 1

TF = µ X W

TF = Required tangential force

W= Weight of article to be transferred

µ = Coefficient of rolling friction in accordance with the material composition

of the bottom of the article to be transferred. (See Table I)

TF = µ X W

TF = Required tangential force

W= Weight of article to be transferred

µ = Coefficient of rolling friction in accordance with the material composition

of the bottom of the article to be transferred. (See Table I)

- To determine the number of POWER MOLLER units required for transfer, compare required tangential force (F) and the tangential force of one POWER MOLLER unit (f)

Formula 2

Number of POWERMOLLERS required = F/f

Number of POWERMOLLERS required = F/f

The above values are based on industry standards of products with a smooth, uniform bottom surface in contact with the roller.

Example

- Material: Cardboard

- Weight: 25 lbs.

- Voltage: 3Phase, 230VAC @ 60Hz

- Speed: 85 FPM

- Diameter: 2.25”

- BF: 24”

- Options: None

A – Tangential force required (Formula 1)

Given W = 25 lbs.

Cardboard coefficient = 0.11

TF = X W

TF = 0.11 X 25 lbs.

Cardboard coefficient = 0.11

TF = X W

TF = 0.11 X 25 lbs.

TF = 2.75 lbs. required to move the article

PM570AS-20 TF – 5.4 lbs. > 2.75 lbs. ((Refer to catalog page for chosen roller to obtain performance data)

PM570AS-20 TF – 5.4 lbs. > 2.75 lbs. ((Refer to catalog page for chosen roller to obtain performance data)

B – Match/Best fit the diameter

- Diameter given 2.25” (57.0 mm)

- Model: PM570

C – Given AC motor type

- Model number/motor type reflects AC or DC

- PM570AS

D – Select the best speed for the customer

- Speed code is an approximate meter-per-minute figure

- Varies by model

- Reference FPM values

- See speed table for PM570AS, (Refer to catalog page for chosen roller to obtain speed codes)

- Given 85 FPM, Speed code -20 offers 89.6 FPM

Model number with speed code: PM570AS-20

E – Maximum Load Limit

- See maximum static load limit table, page 60

- PM570 series

- 500 – 600 mm tube length

- Maximum load limit of 176 lbs. per roller

- 25 lbs. load < 176 lbs. limit – Okay

F – Select the correct voltage

PM570AS is an AC motor type

PM570AS is an AC motor type

- Available voltage is 3 phase, 230VAC @ 60Hz

- Model number with voltage – PM570AS-20-595-3-230

G – Options

- No options given

Final model number: PM570AS-20-595-3-230

Description

- 2.25” Diameter

- Standard AC motor type

- 90.1 FPM

- 595 mm Tube Length

- 3 230 VAC @ 60 Hz

- No Options